Sometimes pulling a thread on a piece of clothing is a bad idea, but perhaps on an offshore yacht it’s a good idea. A simple fuel bleeding recently led to a full haulout and weeks of work on Dog Star.

During the rigging refit I noticed that the engine was running rough as we motored to the fuel dock, just before we arrived the engine stopped! Thankfully we were only moving slowly and there was no wind, so after a quick prayer to Huey the engine spluttered into life and we finished the job. Later inspection found the fuel line’s hose clip had come loose on the secondary fuel pump. I tightened it up and began bleeding the engine. We had a bit of trouble and so asked our mechanic to show us around the engine and teach us how to properly bleed it.

“While you’re there mate, what do you think of the PSS seal?”

“I think it’s in a pretty bad state, I don’t want to freak you out, but you need to replace that immediately.”

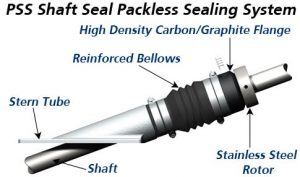

A PSS seal is a dripless shaft seal, it uses a carbon disc and a steel disc facing each other to create a seal, one face spins, the other is static. The very fine clearance between the discs creates a complete seal. Ours was a dripping dripless seal, which is what freaked out the mechanic.

Diagram of PSS Seal

We hauled our Dog Star out and had Travis come checkout the boat and replace the shaft seal, we asked him to look at our faulty ShaftLok at the same time, the lock mechanism was totally worn out and never worked. In the process of pulling this off, our mechanic found more bad news. Someone had decided to try and “fix” the shaftlok by drilling a number of holes in the shaft….

…the horror…

6 holes like this

A 70hp motor pushing 12 tons of boat through the water generates a huge amount of twisting force, our 1.25 inch shaft was already at the lower end of the recommended size for our boat and engine combo. This meant a new shaft, which meant a hole drilled in the skeg to remove it. The worst thing about a sheared shaft would be the combination of water flooding into the engine compartment and no drive after plugging the leak.

The thread however, continued to unravel. In the process of removing the propellor I noticed it was very brittle and crumbly, years of poor maintenance meant that at some point there was probably no anode on the shaft, and the propellor acted as an anode in its place, electrolysis had stuffed it.

Now we await a new shaft and prop to arrive and be fitted, but the good news is, we are ditching the shaftlok and going for a Flexofold prop, which should mean silent and faster sailing when the motor isn’t running.

All in all, I see this as a good thing. Bit by bit we’re finding and fixing everything, I know once we’re 500 miles from anywhere, I’ll sleep better knowing this has all been found and sorted. There is more to the unravelling, but I’ll save that for the next post.

Recent Comments